We provide a completed service to make the orders: caps&hats style confirmed, fabric maetrial &color chosen,closure chosen, logo and decorations techniques,hats&caps fnishing details,mass production, packing, inspeciton and loading into container.

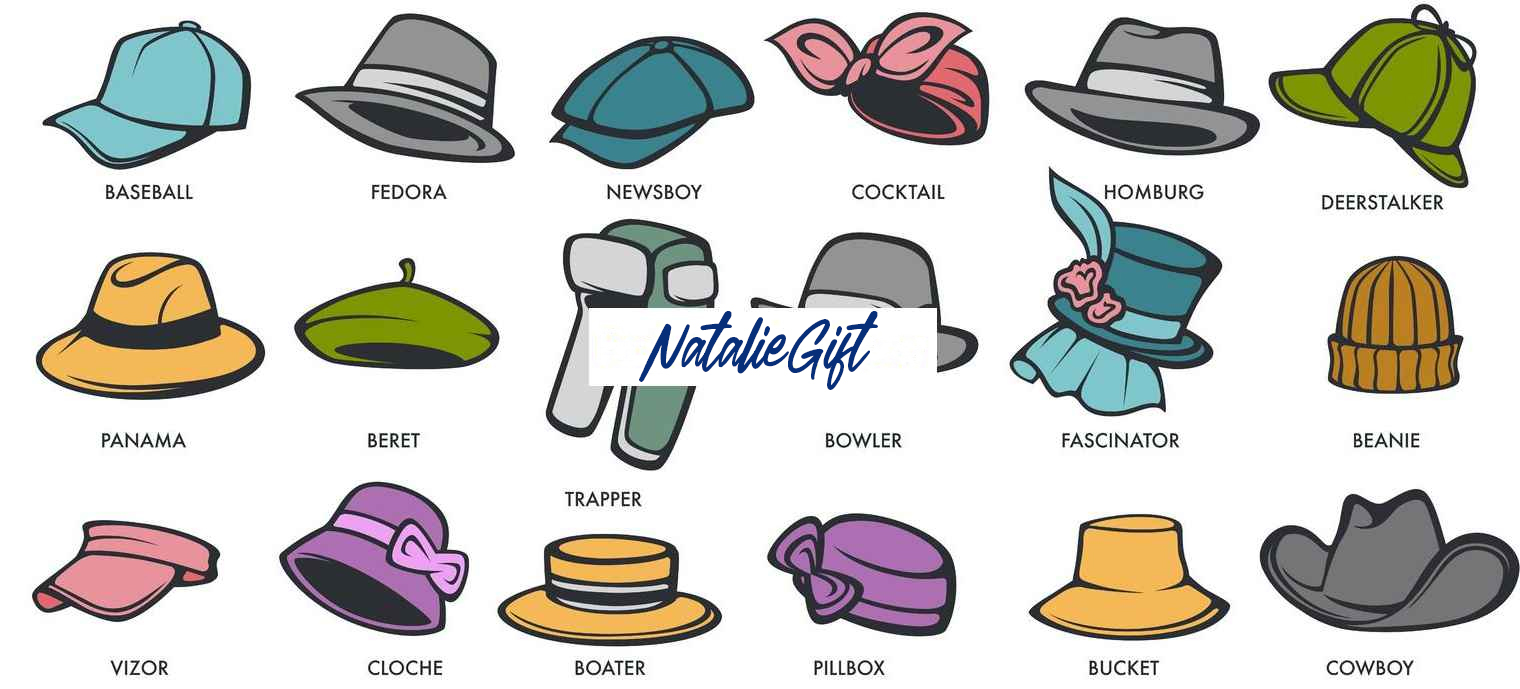

Step 1 : Confirm Style

As there are so many styles of caps&hats in market like baseball cap, beanies, truck cap, visor, straw hat and so on, the first step is to confirm the style you prepare to import.

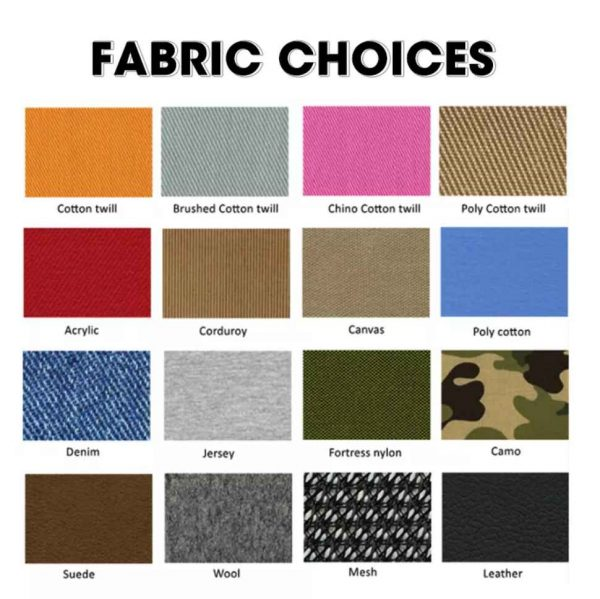

Step 2 : Confirm Fabric

Many material available like Cotton,Polyester,R-PET(recycle material),PU,Leather,Nylon and so on.

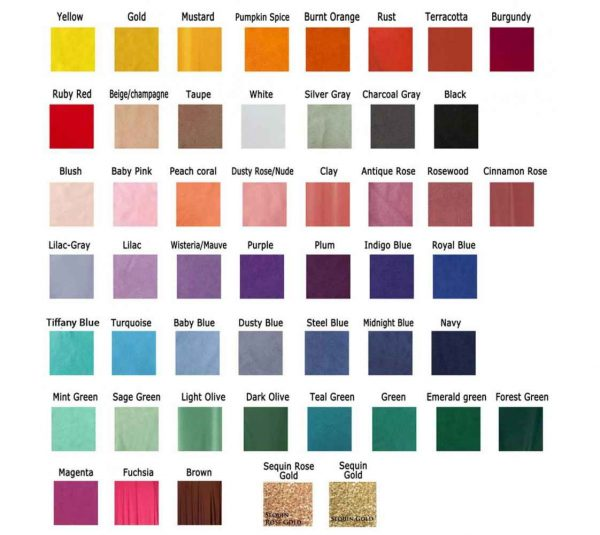

Step 3: Confirm Colors

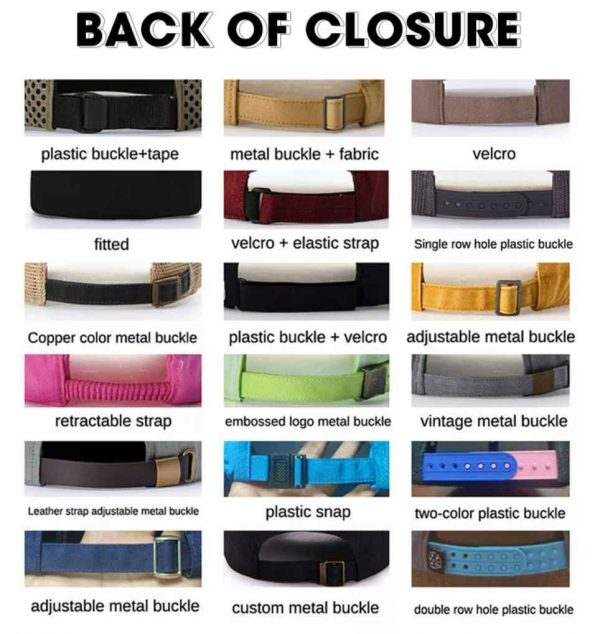

Step 4: Confirm Closure

In the backside,various of closures like metal buckle,plastic closure,velcro and so on.

Step 5: Confirm Logo

For custom logo, too many process:printing logo, embroidery logo, woven patch with custom logo, metal plate with custom logo and so on.

Step 6: Confirm Rest Details

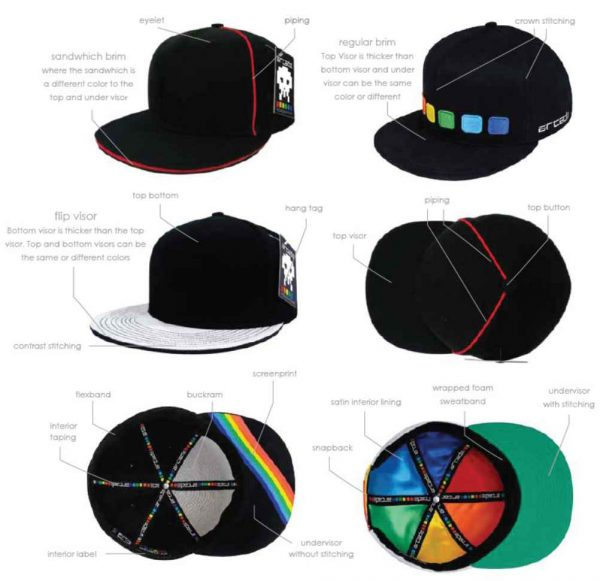

Various of details like seamband,sweatband,sandwich,trimming,eyelets,top button and so on.

Step 7: Mass Production + Inspection

After PP sampels confirmed, then we go ahead mass production, all working lines will be in our own workshop,we have high quality control , do 3 times inspection , before mass production start, we will inspect all of raw material, during the mass production , we will do a middle inspection and after all goods finished, we will do a final inspection and then take all goods in our warehouse for shipment.